Tips for working with the circular table saw

With the circular table saw you can make the most varied cuts in wood with precision. However, there are a few things you must bear in mind when using the circular table saw. In particular, safety when operating the circular table saw plays a decisive role. In this article you will learn about how to use the circular table saw correctly, tips for working with the circular table saw and what you should pay attention to.

Important safety measures when dealing with circular table saws

Not only for the unexperienced, but also for ambitious and experienced DIYers, working with the circular table saw involves considerable risks. So, it’s important that you work with the saw very carefully and with concentration to avoid serious injuries due to carelessness. If you have no experience with the saw, read the operating instructions before starting to work with the saw. The following tips for working with circular table saws are particularly helpful:

- Your circular table saw should always have a firm base under its feet, not wobble and stand up straight.

- Use the saw to cut different types of wood lengthwise or crosswise. Sawing other materials, firewood and round wood, on the other hand, is absolutely to be avoided and involves many risks.

- Adjust the cutting height of the saw so that you cut straight through the workpiece. Otherwise the cutting edge will not be as clean and the saw blade will become visible, and you could accidentally reach into it.

- If the distance from the workpiece to the saw blade is less than 120 mm, use a sliding block to guide the workpiece. If the distance is less than 30 mm, use a push stick to guide the workpiece towards the saw blade piece by piece without any risk.

- Do not place your hands on the workpiece in the area of the cutting line when feeding the workpiece. In addition, feed the workpiece in at a constant speed and constant pressure.

- Always remove workpieces or parts of workpieces in the area of the circular table saw blade with the push stick.

- The right saw blade also plays a decisive role: Only fit approved saw blades in your circular table saw to cut materials. Take particular care that the riving knife thickness and the saw blade thickness match.

- For your own safety, always wear mouth, ear and eye protection and tight clothing. You should avoid wearing gloves, as the fabric of the gloves can quickly get caught in the circular table saw. It is also advisable to use a collection container for pieces of material.

When should I use which saw blade?

You will find a wide range of saw blades on the market. However, the saw blades vary considerably in their properties and are not automatically suitable for the exact workpieces you are working on. Basically, the finer the toothing of the blade, the more precise cuts you can make with your saw and the fewer tears there are in the cut edge. In addition, the teeth of the blades for woodworking must always be at a positive angle to the central axis and point downwards. So that you know which blade is best suited for your work, we will show you a short overview of the most common saw blades.

The coarse tooth saw blade for longitudinal cuts

The saw blade with coarse and small toothing is perfectly suited for longitudinal cuts in solid wood. With the saw blade you can saw fast and efficient cuts, because the teeth have a large chip space. However, you must be aware that this will cause severe tearing at the cutting edge.

The universal saw blade for wood‐based materials

The universal saw blade is particularly suitable for wood‐based materials. The blade has more teeth than a coarse tooth saw blade. In addition, the teeth and chip space are generally smaller, which prevents larger tears on the cutting edge.

The fine tooth saw blade for cuts across the grain

If you want to avoid tears on the cutting edge as much as possible, a fine tooth saw blade is the right choice for you. It is important that you always cut across the wood grain. This blade is also suitable for processing coated workpieces.

How to properly use circular table saws

Now that you know what you need to know when working with the saw, you can start sawing. Make sure that the circular table saw is set correctly, because this is essential for a clean and precise cut. The crosscut fence, scale and rip fence are very important. In the following we will explain the most important adjustment ranges of the saw and its functions in detail.

Crosscut fence

Make sure that your saw has a crosscut fence. With the crosscut fence, you can make very precise angle cuts, for example. The crosscut fence on Einhell’s circular table saw is designed for mitres of –60° to 60°.

Scale

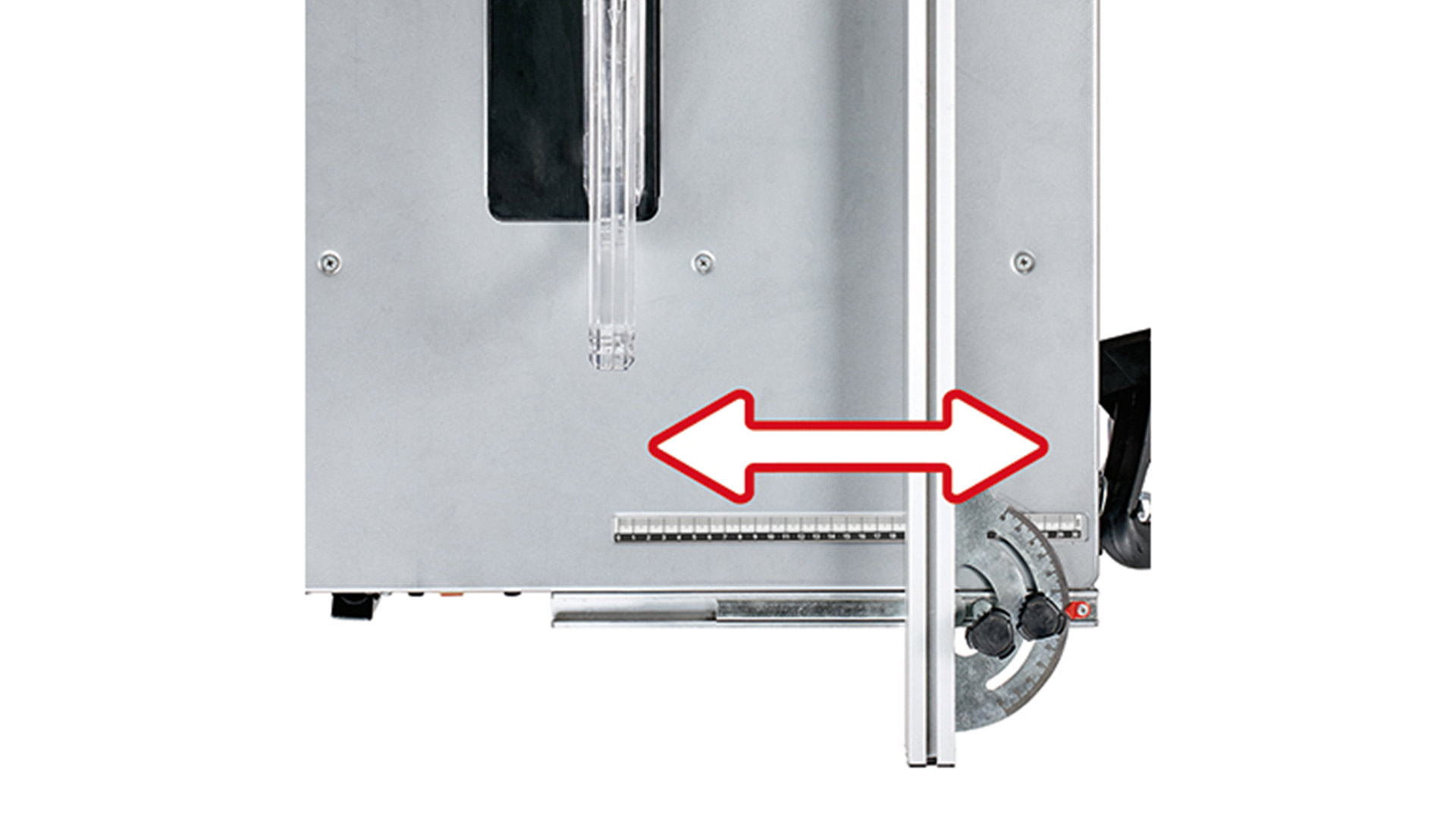

Also always make sure that the distance between the rip fence and the saw blade is set correctly. With the scale you can adjust the distance of the rip fence to the saw blade so that the cut‐to‐length saw blade always has the same length and width and an identical cut is made.

Rip fences

With the rip fence you push the workpiece through the circular saw with a push stick along the rip fence. Thanks to the rip fence, the workpiece is always the same distance from the blade, which enables an exact cut. It is also important that you always fix the rip fence and that it is not too loose.

Once you have made all the adjustments, you can start sawing. Always mark the cuts precisely and cleanly, and always work carefully and in a concentrated way with the saw. See below in the video which special features the machine has in store for you:

Summary:

As you can see, the circular table saw can be used for a variety of different applications and requires a great deal of sensitivity. In addition to careful handling of the machine, there are many other points to consider so that you avoid serious injuries and can achieve optimum results. However, with our tips you are guaranteed safe and optimal saw cuts for all your DIY projects. Become an Enabler!